|

|

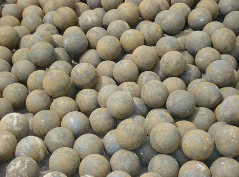

Custom Mining Forged Steel Balls Grinding Media For Ball Mill

|

Product Details:

Payment & Shipping Terms:

|

| Application: | Mine Mill | Material: | Steel |

|---|---|---|---|

| Dimensions: | As Per Drawings | High Cr Cast Ball Hardness: | HRC≥60 |

| Product Name: | Grinding Media | OEM: | YES |

| Highlight: | hollow steel balls,steel ball manufacturer |

||

Custom Mining Forged Steel Balls Grinding Media For Ball Mill

Mining Forged Steel Balls

1. Hardness difference from surface to center is less than HRC3.

2. Hardness:More than HRC60.

3. Surface of castings is free from burnt sand & smooth.

4. It is free from hard spot, visible injurious defects such as blow hole,porosity, shrinkage, cracks,

cold-shuts.

Specification available

A. Cast Balls

(1) Diameter (mm): φ140, φ125, φ110, φ100, φ90, φ80, φ70, φ60, φ50, φ40, φ30, φ20, φ17, φ15

B. Cast Cylpebs

(1.2)Diameter (mm): φ35×40, φ30×35, φ25×30, φ20×25, φ18×18, φ16×16, φ15×20, φ14x14,

φ12×16, φ12x12, φ10×12, φ10×10, φ8×8

(2) General Mechanical Property

|

Materials |

Hardness |

Impact value |

Wear in Cement Mills (g/mt) |

Application Field |

|

High Cr Cast Iron |

≥HRc60 |

≥4J |

25-60 |

The dry-grinding process in cement works, power plants and wet-grinding process in mine; |

|

Low Cr Cast Iron |

≥HRc46 |

≥3J |

≤130 |

The dry-grinding process in cement works, power plants and wet-grinding process in mines |

(3). The Detailed Information about Diameter 60mmCast Balls with Different Cr Content

|

Composition (%) |

C |

Si |

Mn |

Cr |

P |

S |

Hardness (HRC) |

Wear Rate in Gold Mine |

|

Low Cr Cast Balls |

2.0~3.0 |

0.5~1.5 |

≤0.50 |

1.5~2.5 |

≤0.07 |

≤0.07 |

46~55 |

About 1000g/MT |

|

Mid Cr Cast Balls |

2.0~3.5 |

≤1.0 |

0.3~1.2 |

4.0~6.0 |

≤0.10 |

≤0.10 |

≥50 |

About 870g/MT |

|

Cr12 Cast Balls |

2.0~3.0 |

≤1.2 |

0.7~2.0 |

10~12 |

≤0.06 |

≤0.06 |

≥55 |

≤820g/MT

|

|

Cr15 Cast Balls |

2.0~3.0 |

≤1.2 |

0.7~2.0 |

14~16 |

≤0.06 |

≤0.06 |

≥58 |

|

|

Cr20 Cast Balls |

2.0~3.5 |

≤1.0 |

0.5~1.5 |

17~23 |

≤0.06 |

≤0.06 |

≥60 |

≤760g/MT |

C. Forged Steel Balls

(1). Diameter (mm): φ150, φ140, φ130, φ120, φ110, φ100, φ90, φ80, φ70, φ60, φ50, φ40

The Combined Self-fastened Boltless Ball Mill Liners

This product, invented by Mr. Chen Changshun, senior engineer and the director of the company, is known

as “China Best Liner”.It includes two parts, high wear resistance boltless plates, and highly expandable

riveting plates, which are self-fastened and strengthened to withstand impact from mill balls.

We possess famous patented product------

Combined Self-fastened (Boltless) Ball Mill Liners, or called CHINA BEST LINER.

In 2012, we registered a new patent about Liner Technology.

In December of 2000, we successfully registered the international patent in Canada.

In 1988 and 1997, we claimed domestic patents for ball mill liners .

The outstanding advantage of our liners is boltless.

-

Automatic ABS Chicken Water Feeder Poultry Broiler Ball Valve Nipple Drinkers

-

Shaft 1045 Steel Helical Gear Reducer Speed Reduction Gearbox For Screw Conveyor

-

Customized Ball Mill Parts Steel Casting Hollow Shaft For Industrial

-

Grinding Media Cast Steel Balls With Cylpebs HRC47-55 , Cr5 , Cr8

-

G200 28mm DN Precision Carbon Steel Balls Grinding Steel Ball

-

FORGED GRINDING STEEL BALL FOR CHEMICAL INDUSTRIES