|

|

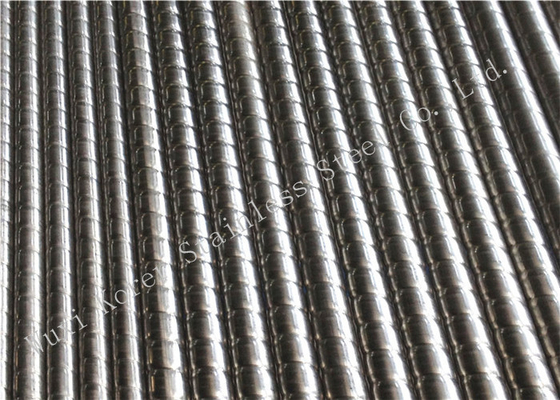

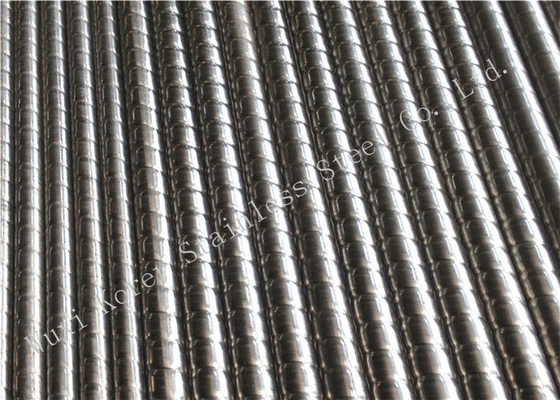

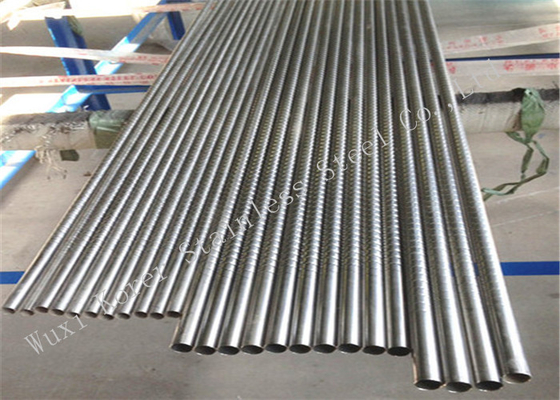

Small Diameter Threaded Stainless Steel Pipe / Circular TIG Welding SS Tube with TP316L

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Threaded SS Pipe / Tube | Material Grade: | TP316L |

|---|---|---|---|

| Application Filed: | Condenser / Heat Exchanger | Pipe Type: | Longitude Welding |

| Standard: | ASME SA249/DIN 17457 / EN10217 | Delivery Condition: | Bright Annealing |

| Highlight: | stainless steel threaded pipe,threaded stainless steel tube |

||

Circular TIG Welded Threaded SS Pipe / Tube For Thermal Power Generation

Quick detail:

Name | Threaded SS Pipe / Tube | Pipe Type | Longitude Welding |

Standard | ASME SA249/DIN 17457 / EN10217 | Delivery Condition | Bright Annealing |

Brand Name | KORER | Application Filed | Condenser / Heat Exchanger |

Description:

Stainless Steel Coil | |||||

Item | 1 | 2 | 3 | 4 | 5 |

Brand | POSCO | BAO STEEL | KRUPP | TISCO | OUTKUMPU |

Material:

American Standard | Austenitic Steel: |

TP304,TP304L,TP304H,TP304N, TP310S,TP316,TP316L,TP316Ti,TP316H, | |

TP317,TP317L, TP321, TP321H,TP347, TP347H,904L… | |

Duplex Steel : | |

S32101,S32205,S31803,S32304,S32750, S32760 | |

Others:TP405,TP409, TP410, TP430, TP439,... | |

European Standard | 1.4301,1.4307,1.4948,1.4541,1.4878,1.4550,1.4401,1.4404,1.4571,1.4438, |

1.4841,1.4845,1.4539,1.4162, 1.4462, 1.4362, 1.4410, 1.4501 | |

Russia Standard | 08Х17Т,08Х13,12Х13,12Х17,15Х25Т,04Х18Н10,08Х20Н14С2, 08Х18Н12Б, |

10Х17Н13М2Т,10Х23Н18,08Х18Н10,08Х18Н10Т, 08Х18Н12Т,08Х17Н15М3Т, | |

12Х18Н10Т,12Х18Н12Т,12Х18Н9, 17Х18Н9, 08Х22Н6Т, |

Applications Fields:

Industry | Applications |

Thermal Power Station | Condenser Tube |

Nuclear Power Staition | Condenser Pipe |

Specifications:

1)Product Name: Threaded SS Pipe / Tube |

2)Standard: ASME SA249/DIN 17457 / EN10217 |

3)Material Grade:Austenitic / Feritic / Duplex Stainelss Steel |

4)Outer Diameter:6mm-50.8mm |

5)Wall Thickness:0.3mm – 2.5mm |

6)Length:Depends on Customers’ Request |

7)Tolerance:According to ASME SA249/DIN 17457 / EN10217 |

8)Leakage Test:ET Or Hydraulic Test Or Air Pressure Test Under Water |

9)Main process:Welding, Annealing |

10)Certificate:ISO 9001:2008, Manufacture License Of Pressure Pipe |

11)Marking:Brand, Standard, Grade, Size, Length and Heat No. Or Depends On Customer. |

12)Packing:Bundles With Plastic Bags, Wooden Box With Angle Steel Frame Or others |

13)Payment Terms:T/T, L/C at sight |

14)Delivery Time:Generally 15Days – 45Days Or Depends on the quantity and Customers’ Request |

15)Capacity:1000 Tons Per Month |

Competitive Advantage:

We have nearly 20 years of experiences in producing high quality Welded stainless steel Pipes / Tubes,We Are Approved By ISO 9001 And Manufacture License Of Pressure Tubes,The Raw Material are from Big Company,Such as POSCO,BAO STEEL,TISCO,CRUPP Etc.Our Good Quality Based On the high technical production line And Steady Technicians,We have win high reputation based on good quality With Our Customers.

Test System:

Corrosion Test | Conducted only when specially requested by the client |

Chemical Analysis | Test done as per required quality standards |

Destructive / Mechanical Testing | Tensile | Hardness | Flattening | Flare | Flange |

Reverse-bend and Re. flat tests | Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

Eddy Current Testing | Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

Hydrostatic Testing | 100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

Air Under Pressure Test | To check any evidence of air leakage |

Visual Inspection | After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Parts of Achivements | |||

PROJECT NAME | MATERIAL | SPECIFICATION(mm) | Q’TY(T) |

Shang an 6# Condenser | TP317L | 22 x 0.5 / 0.7 | 80 |

Indian JSW6 - 8# Condenser | TP304 | 20x 0.5 / 0.7 | 130 |

Indian J Plant 3# | TP304 | 25 x 0.5 / 0.7 | 170 |

Nanre 1# 2# Condenser | TP304 | 25 x 0.5 / 0.7 | 340 |

Xingchang 1# 2# Condenser | TP304 | 25 x 0.5 / 0.7 | 340 |

Indina BALC01# 2# 3# | TP304 | 28 x 0.5 / 0.7 | 240 |

Indian WPC4# | TP304 | 20 x 0.5 / 0.7 | 40 |

Anbala 1# | TP304 | 25 x 0.5 / 0.7 | 170 |

Indian oil condenser 8SETS | TP316L | 16 x 0.7 / 0.8 / 1.0 | 60 |

Fuqing 1#/2#,Fangjiashan 1#/2# | TP304 | 19 x 0.9 x U | 89 |

Indian K Plant 1# 2# | TP304 | 25 x 0.7 | 360 |

Fangjiashan Nuclear Project | TP304 | 19.05 x 0.91 x U | 86 |

Indian Chhattisgarh Power 1# 2# | TP304 | 25 x 0.7 | 370 |

Zambia 1# 2# | TP316L | 22 x 0.7 / 0.9 | 190 |

Qilu Petrochemical Plant | TP316L | 38.1 / 50.8 x 1.5 / 2.0 | 15 |

Shandong Beichen(Nuclear) | 316L | 16 x 1.2 x U | 150 |

Huali Petrochemical Plant | TP304L | 38.1 / 60.3 x 1.5 / 2.1 | 330 |

Dongsheng Petrochemical Plant | TP304 | 16 / 25.4 x 1.24 / 1.5 | 480 |

Pushin(Petrochemical application) | TP304 | 50.8 / 38.1 x 1.2 / 2.1 | 1232 |

Nanjing steam turbine works(Condenser) | 304/316L | 16 / 19 x 1.2 / 1.5 | 40 |

Spainish Customer | TP316L | 31.8 / 38.1 x 1.2 x 2.1 | 230 |

304 | 44.5 / 50.8 x 1.2 / 1.5 | 190 | |

Germany Customer | 304/316L | 25.4 / 42.4 x 1.5 / 2.0 | 320 |

Pakistan Customer | 304 | 42.4 x 1.5 x 12000 | 150 |

-

6000mm Stainless Steel Welded Tubes SS 201 Stainless Steel Round Pipe 400# 600# 800#

-

Square Stainless Steel Welded Pipe / 304 Stainless Steel Square Tubes

-

Embossed finish 316 HL 304 rectangular Stainless steel welded pipes nitrogen protection

-

Circular Stainless Steel Welded Pipe 20mm With DIN 17455 / DIN17457

-

Grade 201 114*3.0mm Polished Stainless Steel Pipe For Decorations

-

ASTM 304 stainless steel welded pipe