|

|

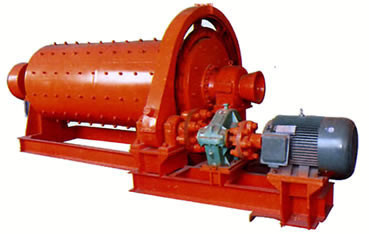

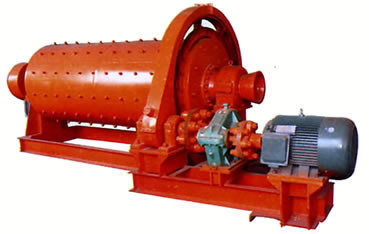

Energy saving wet grinding ball mill, ball grinder, high efficiecy grinding machine

|

Product Details:

Payment & Shipping Terms:

|

Overflow Type Wet Ball Mill Machine grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground. The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill. The larger the diameter, the slower the rotation. If the peripheral speed of the mill is too great, it begins to act like a centrifuge and the balls do not fall back, but stay on the perimeter of the mill. The point where the mill becomes a centrifuge is called the "Critical Speed", and ball mills usually operate at 65% to 75% of the critical speed.

Overflow Type Wet Ball Mill Machine Application:

Overflow Type Wet Ball mill are generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns. To achieve a reasonable efficiency with ball mills, they must be operated in a closed system, with oversize material continuously being recirculated back into the mill to be reduced. Various classifiers, such as screens, spiral classifiers, cyclones and air classifiers are used for classifying the discharge from ball mills. Ball mill is an efficient tool for grinding many materials into fine powder. The ball mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the dry process and the wet process. It can be divided into tabular type and flowing type according to different forms of discharging material.

Overflow Type Wet Ball Mill Machine Features:

(1)Use double row stone roller spherical bearings, spindle aperture narrowed considerably, can reduce the weight of mill and reduce friction torque, reduce useless consumption, while ensuring automatic heart, extended service life, simple, easy maintenance.

(2)Transmission part:

Gearwheel installed in the link site of vertical silo and cone, improve the force of main bearings part, reduce the distortions of the cylinder stress, gear module and a corresponding reduction in diameter, so that reduce weight of ball mill, reduce the load.

(3)Drive part

Efficient energy-saving ball mill’s motor power 20-40 percent lower than conventional mill’s, use this series ball mill can get more social and economic benefits, only because of energy-saving, you can recover mill investment costs in 2-3 years.

Overflow Type Wet Ball Mill Machine Working Principle:

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

| Model | Cylinder Rotation speed (r/min) | Ball loading(T) | Feeding Size(mm) | Capacity (t/h) | Motor Power (KW) | Overall Dimension (mm) L*W*H | Weight (Kg) |

| GM912 | 41.6 | 1.1 | 25 | 0.3~0.9 | 11 | 3843*1850*1400 | 4210 |

| GM921 | 41.6 | 1.8 | 25 | 0.6~1.5 | 15 | 4743*1850*1400 | 6660 |

| GM933 | 41.6 | 2.8 | 25 | 0.9~2.3 | 30 | 5943*1850*1400 | 7770 |

| GM1224 | 35.1 | 4.0 | 25 | 1.6~4.1 | 37 | 5540*2300*1850 | 10020 |

| GM1228 | 35.1 | 4.6 | 25 | 1.9~4.8 | 45 | 5940*2300*1850 | 10935 |

| GM1232 | 35.1 | 5.3 | 25 | 2.2~5.5 | 45 | 6340*2300*1850 | 11230 |

| GM1244 | 35.1 | 7.3 | 25 | 3.0~7.5 | 55 | 7540*2300*1850 | 13210 |

| GM1324 | 30.2 | 4.5 | 25 | 1.5~3.5 | 37 | 5035*2370*1880 | 10210 |

| GM1328 | 30.2 | 5.2 | 25 | 2.0~4.5 | 45 | 5435*2370*1880 | 11290 |

| GM1334 | 30.2 | 6.5 | 25 | 2.2~5.0 | 75 | 6035*2370*1880 | 13117 |

| GM1524 | 30.7 | 7.0 | 25 | 2.8~6.5 | 55 | 6830*2930*2060 | 15430 |

| GM1530 | 30.7 | 9.0 | 25 | 3.5~8.0 | 80 | 7430*2930*2060 | 16843 |

| GM1533 | 30.7 | 10.0 | 25 | 4.0~9.0 | 95 | 7730*2930*2060 | 17849 |

| GM1536 | 30.7 | 11.0 | 25 | 4.5~10.0 | 95 | 8030*2930*2060 | 18649 |

| GM1542 | 30.7 | 12.5 | 25 | 5.0~11.0 | 110 | 8630*2930*2060 | 19330 |

| GM1545 | 30.7 | 13.5 | 25 | 5.5~13.5 | 110 | 8930*2930*2060 | 20000 |

| GM1557 | 30.7 | 17.0 | 25 | 7.0~15.5 | 130 | 10130*2930*2060 | 23597 |

| GM1563 | 30.7 | 19.0 | 25 | 8.0~17.0 | 155 | 10730*2930*2060 | 24390 |

| GM1830 | 25.04 | 13.0 | 25 | 3.0~17.0 | 130 | 9525*3960*2250 | 29490 |

| GM1834 | 25.04 | 14.0 | 25 | 3.3~20.0 | 155 | 9925*3960*2250 | 30390 |

| GM1836 | 25.04 | 15.0 | 25 | 4.0~21.5 | 155 | 10125*3960*2250 | 31600 |

| GM1840 | 25.04 | 17.0 | 25 | 4.5~24.0 | 155 | 10525*3960*2250 | 32700 |

| GM1842 | 25.04 | 18.0 | 25 | 5.0~25.0 | 180 | 10725*3960*2250 | 33490 |

| GM1844 | 25.04 | 19.0 | 25 | 5.2~26.0 | 180 | 10925*3960*2250 | 34210 |

| GM1852 | 25.04 | 21.0 | 25 | 6.5~32.5 | 180 | 11725*3960*2250 | 37715 |

| GM1864 | 25.04 | 27.0 | 25 | 8.0~40.0 | 210 | 12925*3960*2250 | 42440 |

| GM2122 | 23.8 | 15.0 | 25 | 3.0~22.0 | 130 | 7775*4060*3400 | 38793 |

| GM2130 | 23.8 | 20.0 | 25 | 4.0~30.0 | 180 | 8475*4060*3400 | 41965 |

| GM2136 | 23.8 | 21.0 | 25 | 5.0~37.0 | 210 | 9225*4060*3400 | 44551 |

| GM2140 | 23.8 | 22.0 | 25 | 5.2~39.0 | 245 | 9475*4060*3400 | 46697 |

| GM2145 | 23.8 | 25.0 | 25 | 5.6~42.0 | 280 | 9975*4060*3400 | 49230 |

| GM2436 | 23 | 26.6 | 25 | 6.5~82.0 | 280 | 9770*5005*3970 | 63684 |

| GM2444 | 23 | 32.5 | 25 | 8.0~100 | 380 | 10570*5005*3970 | 72284 |

| GM2736 | 21.7 | 34.0 | 25 | 15.0~115 | 420 | 10575*5610*4500 | 88400 |

| GM2745 | 21.7 | 40.0 | 25 | 17.5~135 | 475 | 11175*5610*4500 | 90420 |

| GM3230 | 18.7 | 44.0 | 25 | 50.0~90.0 | 500 | 11000*7200*5700 | 124000 |

| GM3245 | 18.7 | 65.0 | 25 | 100~145 | 630 | 13000*7200*5700 | 145000 |

-

Ferro Silicon Magnesium Nodularizer

-

Ferro Silicon Magnesium Alloy

-

Rare Earth Ferro Silicon Magnesium

-

FeSiMg alloy / Ferro Silicon Magnesium 5 - 25mm , Si 45% Max For Casting

-

Rare Earth SiMg Alloy , Ferro Silicon Magnesium Alloy For Steelmaking

-

Ferro Silicon Magnesium For Castings Welding With MgO 1.0% Max, Ca 1.5-3.0%