|

|

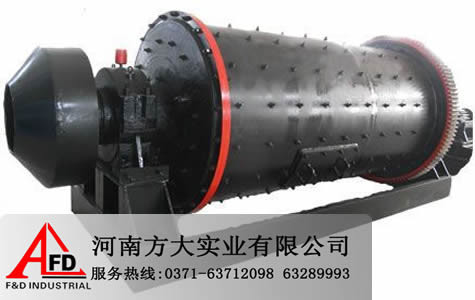

Energy conservation and environmental protection of ball mill|Ball mill in mines

|

Product Details:

Payment & Shipping Terms:

|

![]()

Ball mill for grinding various ores and other materials, is widely used in mineral processing, building materials and chemical industry, can be divided into two kinds of dry and wet grinding method.According to different ways of discharge, can be divided into lattice type and overflow type two.According to the shape of barrel can be divided into short tube ball mill, long tube ball mill, tube milland conical mill four.

After the ball mill is the material being broken, and then smash the key equipment. Mill widely used in cement, silicate products, new building materials, refractory materials, chemical fertilizer, blackand non-ferrous metal processing, such as glass ceramics industry production, various ores andother materials may be grinding of dry or wet grinding.

After overhaul, according to equipment maintenance system acceptance before delivery.

1, before driving around the debris removal equipment, check the Department whether fastening screws, wear checking the spoon head, classifying blade, belt conveyor, feeder is good.

2, check the oil pipe is smooth, the speed reducer oil amount to to swim line, oil quality to meet the quality requirements, the lubricating tool to complete.

3, check the rotating parts and the safety facilities is reliable, electrical appliances parts have nofault.

4, check the pipes, slurry pipeline is unblocked, the site of a non drip phenomenon; check thedischarging chute bottom wear, and remove the tank debris.

5, parking for more than two hours, before the ball mill drive and grading confidential for barring,consolidation of the ore to loose, shock load reducing device startup.

6, examination, confirm the post equipment to normal after, can take off the "maintenance", noticeprocedure and electrician duty room power supply, ready to drive.

The ball mill grinding technological efficiency in grinding, ore dressing has important significancefor improving the. By the closed-circuit grinding process reasonable grinding process should be themineral grains once grinding to the monomer separation should be quickly from the mill wasdischarged. This can avoid grinding, on the other hand, can make the grinding media in the role ofthe coarse ore particles completely, so that the energy can maximize the work. So the grindingspeed, mill productivity. In addition, because the amount of sand return existence, can eliminate themill to mine new fluctuation has influence on product size. Visible, the closed-circuit grinding can effectively avoid crushing and "coarse" phenomenon. It can make the grinding operation under the premise of ensuring qualified granularity, the uniform and coarse narrow level of product, this to the next step of separation is beneficial.

Grinding process of ball mill is generally wet grinding, but in some cases also by dry grinding. Ballrotation, called the hybrid mixture medium, ore and water load close mixing; according to the different speed mill, medium can pass through any kind of crushing and grinding ore. The ball millrunning speed is very important, because it determines the nature of the product and the amount of wear of mill liner. Practical experience shows, the movement of the steel ball in ball mill grindingtrajectory determines the appropriate speed mill, the rotation speed of the whereabouts of the steel ball can fall on the feed load culet, without down and the lining board, otherwise it will cause rapid wear of the lining board. In addition to laboratory test, the grinding of mineral processing arecontinuous operation, to control the speed of material from one end of ore bin join mill, stay in the machine after the appropriate time by the other end of the overflow mill out. Through the use ofmedia types, mill speed, and to the ore properties and the use of loop type to control the particle size of the product.

![]()

Henan YuKuang Machinery Co., Ltd.

Mobile: +86-15333827088 +86-371-63712098

Email: 15333827088@163.com

QQ: 282446231

Linear Vibrating Screen http://www.cncrusher.com/product-20.html

Cone Crusher |Cone Crusher manufacturer http://www.cncrusher.com/product-11.html

Ball Mill |Ball Mill manufacturer http://www.cncrusher.com/product-18.html

-

Ferro Silicon Magnesium Nodularizer

-

Ferro Silicon Magnesium Alloy

-

Rare Earth Ferro Silicon Magnesium

-

FeSiMg alloy / Ferro Silicon Magnesium 5 - 25mm , Si 45% Max For Casting

-

Rare Earth SiMg Alloy , Ferro Silicon Magnesium Alloy For Steelmaking

-

Ferro Silicon Magnesium For Castings Welding With MgO 1.0% Max, Ca 1.5-3.0%