|

|

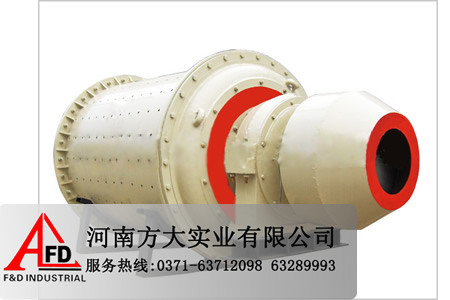

Yukuang 2015 new energy-saving dry cement mill, dry cement grinding ball mill

|

Product Details:

Payment & Shipping Terms:

|

Ball mill machine is the key equipment for recrushing the materials after they are primarily crushed. It is widely used for the dry type or wet type grinding of all kinds of ores and other grindable materials in cement, silicate product, new building material, refractory, fertilizer, black and non-ferrous metals and glass ceramic industry. The ore grinding methods of ball mill include dry type and wet type.

Ball mill machine is mainly composed of feeding part, discharging part, rotary part and driving part which includes reducer, small drive gear, electrical machine and electronic control. The hollow shaft uses steel casting, the inner lining can be dismantled and changed, and the rotary rack wheel uses casting gear hobbing and inside the cylinder there is wear-resisting lining board which has fine abrasion performance. This machine has stable operation and reliable performance.

![]()

![]()

Materials spirally and evenly go into the first cabin of the grinding machine through the feeding hollow shaft from the feeding device, and inside the first cabin, there are ladder lining boards or ripple lining board in which there are many steel balls with different specifications. The cylinder rotates and produces eccentric force to bring the steel balls to a certain height, and then the steel balls will fall down to impact and grind the materials. After being coarsely ground in the first cabin, the materials will go through the single-layer partition board and into the secondary cabin in which there are flat lining board, and in the lining board there are steel balls to further grind the materials. Finally the powdery materials will be discharged from the dis

![]()

2. Cement Ball Mill grinding ball mill price stone grinding machine ball mill Types and feature:

a. dry and wet types.

b. lattice and overflow types, or center-discharge and side-discharge types

c. Bearing MiII and Bushing MiII

d. edge and center types

Notes: other type of mill, like rod mill, ceramic ball mill is also supplied.

![]()

3. Cement Ball Mill grinding ball mill Working Principle:

The Cement Ball Mill grinding ball mill price stone grinding machine ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

4. Cement Ball Mill grinding ball mill price stone grinding machine ball mill Technical Parameter:

|

Shell rotation speed(r/min) |

Ball load(t) |

Feeding size(mm) |

Discharging size(mm) |

Capacity (t/h) |

Motor power(kw) |

Weight(t) |

|

|

Ø900*1800 |

36-38 |

1.5 |

<=20 |

0.075-0.89 |

0.65-2 |

18.5 |

4.6 |

|

Ø900*3000 |

36 |

2.7 |

<=20 |

0.075-0.89 |

1.1-3.5 |

22 |

5.6 |

|

Ø1500*3000 |

29.7 |

7.5 |

<=25 |

0.074-0.4 |

2-5 |

75 |

15.6 |

|

Ø1500*4500 |

27 |

11 |

<=25 |

0.074-0.4 |

3-6 |

110 |

21 |

|

Ø1830*6400 |

24.1 |

21 |

<=25 |

0.074-0.4 |

6.5-15 |

210 |

34 |

|

Ø1830*7000 |

24.1 |

23 |

<=25 |

0.074-0.4 |

7.5-17 |

245 |

36 |

|

Ø2100*3000 |

23.7 |

15 |

<=25 |

0.074-0.4 |

6.5-36 |

155 |

34 |

|

Ø2100*4500 |

23.7 |

24 |

<=25 |

0.074-0.4 |

8-43 |

245 |

42 |

|

Ø2100*7000 |

23.7 |

26 |

<=25 |

0.074-0.4 |

8-48 |

280 |

50 |

|

Ø2700*4000 |

20.7 |

40 |

<=25 |

0.074-0.4 |

12-80 |

400 |

94 |

|

Ø2700*4500 |

20.7 |

48 |

<=25 |

0.074-0.4 |

12-90 |

430 |

102 |

|

Ø3200*4500 |

18 |

65 |

<=25 |

0.074-0.4 |

----- |

800 |

137 |

Henan YuKuang Machinery Co., Ltd.

Mobile: +86-15333827088 +86-371-63712098

Email: 153338

-

High Speed 4000rpm Range 6-20mm Ball End Mill Grinder Grinding Machine

-

CE / ISO Dental Endodontic Files With Natural Diamond Powder For Grinding Teeth

-

Cement Grinding Ball Mill Cement for Sale

-

Pearlitic Cr-Mo Alloy Steel Grinding Ball Mill Liners For AG Mill

-

Advanced Dural Y-Tzp Ceramic Grinding Balls Grinding Media

-

CE Approval Concrete Grinding Ball Mill Machine/ Milling Machine